International boat angler, Dave Proudfoot favours plastic ‘tube’ booms over the multitude of wire alternatives. Here he shows you just how quick and easy it is to make custom sliding booms for just pennies.

While many boat anglers use French booms to support flowing traces or indeed much shorter snoods, I have always preferred the angled plastic ‘through-boom’ alternative. These can be bought ready for use, or very quickly knocked together to suit personal length preference and any number of fishing circumstances.

The bent tube boom slides on the line reducing resistance to the fish and its design means that the risk of tangles is greatly reduced.

They are an adaptable piece of kit proving effective when gilling, shading, conger fishing or fishing one of more baits on the seabed either downtide or when uptiding.

However at 70p upwards to buy a single boom they can work out expensive if losses are high fishing over snaggy ground. All is not lost as materials to make your own are readily available from tackle shops or on the internet and these work out at less than 20p each. I buy my tubing from UK Hooks simply because they can also supply the required link-swivels that fit perfectly over the boom.

The tutorial below shows how easy the tube booms can be produced.

Materials required

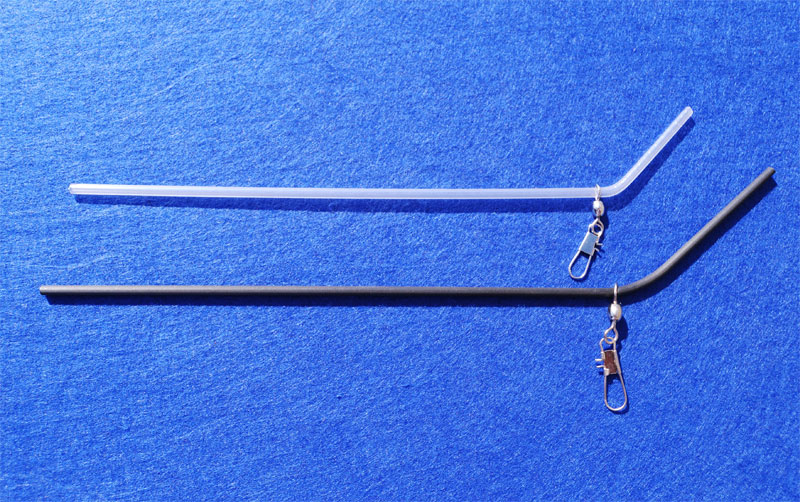

3 – 4mm diameter plastic tubing – UK Hooks can supply this in clear or black in lengths from 225 – 325mm.

Link swivels – the swivel eye should slide tightly onto the tubing. Size matched nickel crane interlock swivels are available from UK Hooks.

Equipment required

Either a kettle or a heat gun with a medium heat setting.

A pair of pliers.

*Warning – Beware of burning your hands in the steam or under the heat gun.

A video showing the bending of the booms using a kettle can be viewed here

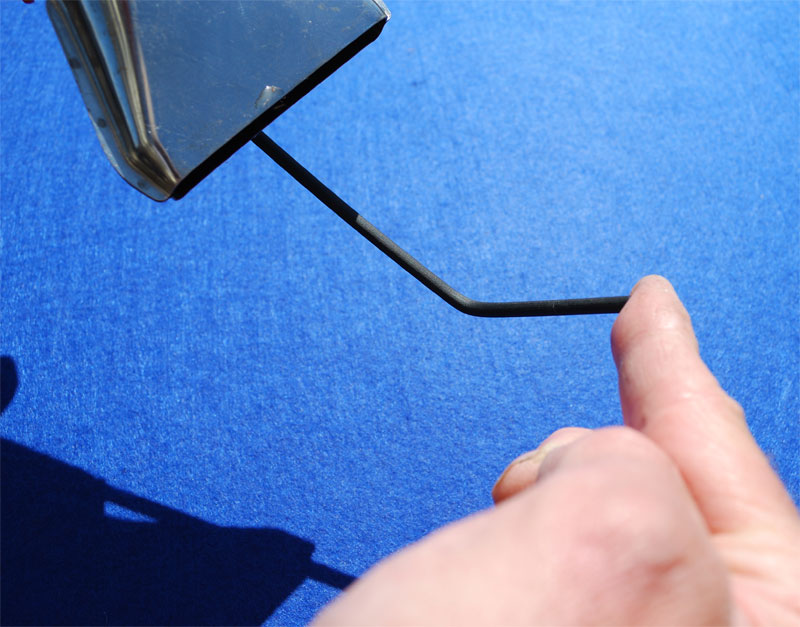

Step 1: Either boil the kettle or warm up the heat gun. Apply heat to the boom using the steam from the boiling kettle or under the nozzle of the heat gun approximately 50 mm from one end. As the tubing starts to soften push the short end upwards until it reaches and angle of between 45 and 70 degrees and immediately remove from the heat source. I don’t find the angle critical but if you wish them all to be the same then cut an angled template from a block of wood and make the bend against that.

Hold the tubing at the angle until it cools slightly then put aside. With practice you should be able to heat and bend three to four booms at once.

Step 1: Either boil the kettle or warm up the heat gun. Apply heat to the boom using the steam from the boiling kettle or under the nozzle of the heat gun approximately 50 mm from one end. As the tubing starts to soften push the short end upwards until it reaches and angle of between 45 and 70 degrees and immediately remove from the heat source. I don’t find the angle critical but if you wish them all to be the same then cut an angled template from a block of wood and make the bend against that. Hold the tubing at the angle until it cools slightly then put aside. With practice you should be able to heat and bend three to four booms at once.

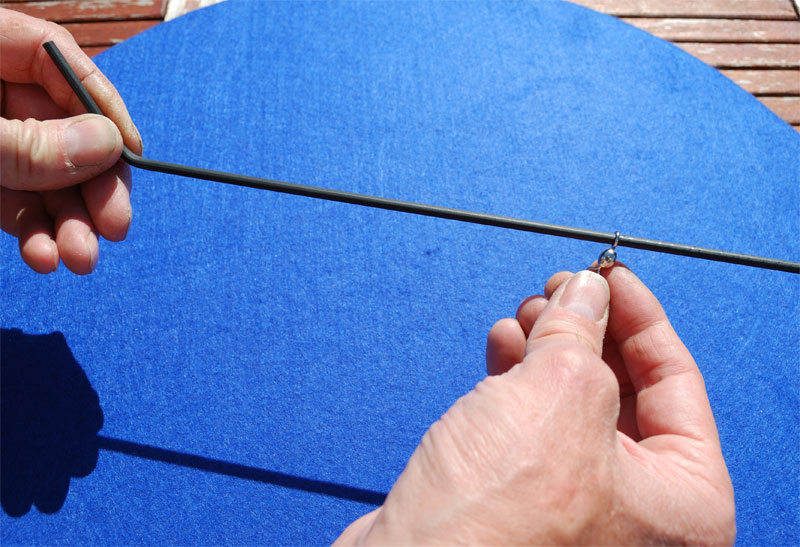

Step 2: Once the booms have fully cooled slip the free swivel eye over the long leg of the boom and work it along until it’s approximately 10 mm from the bend. Rotating the boom while holding the swivel can make the swivel easier to slide along the tubing if it is a tight fit.

Step 3: Gently squeeze the eye of the swivel to secure on the tubing to complete the boom to complete the job.

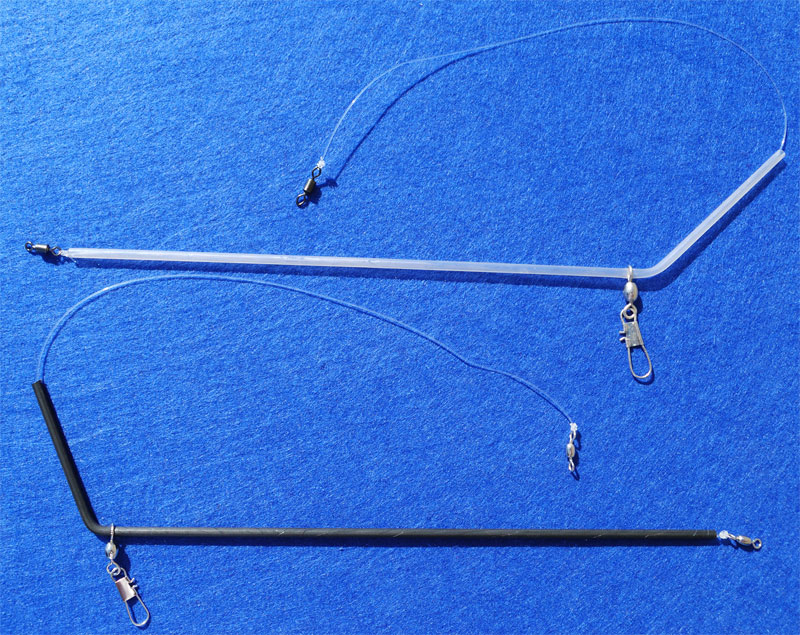

Step 4: I normally pre-tie a 500 mm length of nylon through the boom with a swivel at either end or a link at the terminal end. This makes it easy to change fishing styles and protects the main line from wear and tear through rubbing.