Planet Sea Fishing shows you how to turn a cordless drill and an empty soft drink bottle into a super line stripper that takes the pain out of a regular task that only demented anglers could enjoy.

Stripping old used line from a reel before it can be refilled with fresh mono or braid is a mind-numbing task if carried out by hand. This is the way that the vast majority of anglers de-spool a reel, and it takes an age to see through. Not only that, but the end result is generally a huge tangled ball of knitting on the floor, which is a pain in the backside to gather up and dispose of properly.

A better means is to use one of the several clever little hand-held line stripping devices that are available. These whiz spent line off reels but they spew it just as messily all over the place, despite best efforts to direct the discard into a suitable receptacle. A further downside is that these strippers are quite pricey, and some of the little parts quickly wear out if the unit is used very regularly.

Best of all however is to rattle together your own super line stripper/de-spooler from a handful of bits that most of us will have in the house, garage or shed. All you need is an empty soft drink bottle with the cap attached, a 6mm diameter/60mm long stainless bolt, a 6mm stainless nut, two stainless washers and a cordless drill. Bottles from 500ml to 3 litres all have the same standard sized cap, but smaller bottles are easier to work with. The ‘waisted’ shape of the 500ml bottle tends to keep the line in the one area when stripping.

The pictures below show how 10 minutes can build you a super line stripper that leaves the shop-bought versions standing.

Rather than binning the line please try and use the recycling facilities provided by supporters of the Anglers National Line Recyling Scheme. The line can easily be cut from the bottle and disposed of at one of the many ANLRS recycling points. In any case remember NOT to discard the all important cap drill attachment which is safely stored for next use.

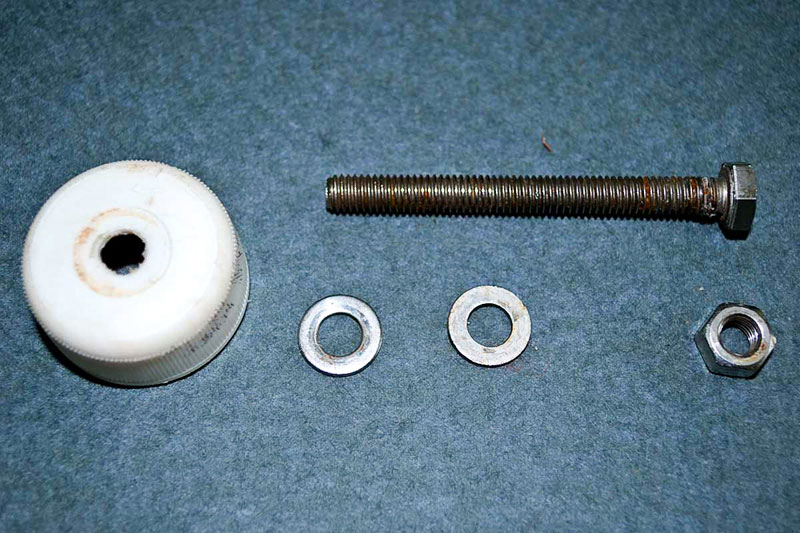

The bits… 1 x empty soft drink bottle with the cap attached, 1 x 6mm diameter/60mm long stainless bolt, 1 x 6mm stainless nut, 2 x stainless washers, Cordless drill (not shown)

Remove the cap and drill a hole to fit the bolt.

Place a washer on the bolt then insert the bolt through the cap from the threaded side. Locate the second washer on the upper side followed by the nut and tighten up against the cap

Attach the cap assembly on to the bottle.

Place the bolt in the drill chuck and you’re ready to go.

Once the line has been stripped from the reel the bottle can be placed straight in the bin with no giant tangle to wrestle with. But remember NOT to discard the all important bottle cap which is yours to use over and over again.

To wind the line back off the bottle you need a second cap; heat a length of welding rod and puncture a hole in the centre of the cap and centrally in the base of the bottle. Thread the wire through the newly created hole in the base of the bottle and out through the neck.

Locate the rod through the hole in the second cap and screw onto the bottle. Heat the end of the rod and puncture a 2cm rubber grommet to assist with applying pressure when re-spooling from the line on the bottle. Repeat at the other end of the wire.