The multiplier reel gets its name because the spool which holds the line is geared to revolve several times for each single turn of the handle. One turn of the handle can rotate the line spool two to seven times depending upon the size and design of the gears.

Multiplier reels generally have a gear ratio listed in their specifications such as 4.7:1 or 6.0:1.The higher the ratio the more rotations of the spool per turn of the handle and vice versa. Large heavy duty reels usually have the smallest gear ratio in order to retain the greater winching power at the expense of the speed of retrieve.

A smaller diameter line spool of an ABU 6500 sized reel geared in a ratio of around 6:1 will give a recovery rate of line between 725mm (25inch) and 975mm (30inch) for each turn of the handle. The rate of retrieve is governed by both the gear ratio and the line capacity of the spool.

Once the sole domain of the big game angler most reel manufacturers now feature twin speed reels in their multiplier range. These reels have a high gear ratio for winding the tackle back at speed and can drop into a lower gear when fighting a heavy fish at the press of a button.

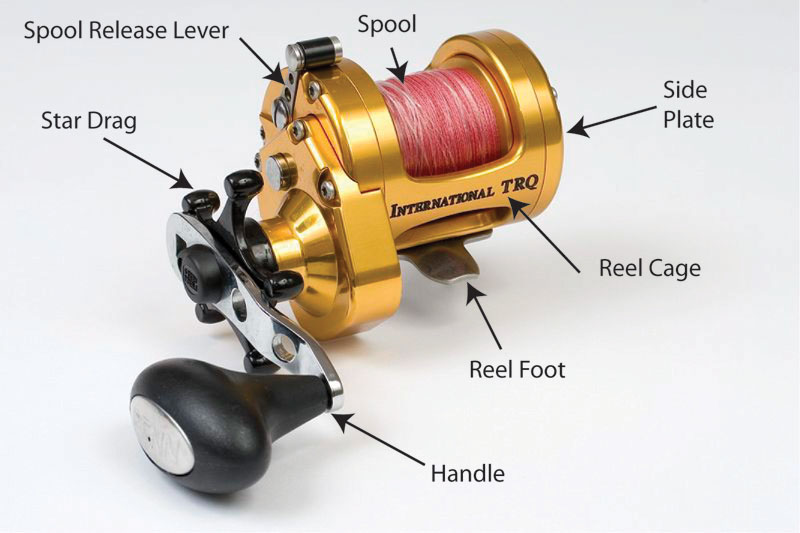

The vast majority of multipliers are mounted on top of the rod with the rings facing upwards. There are a couple of novelty models that are fished under the rod. Most multiplier reels are right handed in use ie the handle is on the right hand side when in use, but several left handed models are available. The reel is fixed to the rod by the reel foot situated on the bottom of the reel and larger boat reels may also feature a securing clamp which attaches to the frame of the reel.

The spool of a star drag multiplier is set into free spool, for casting or lowering from a boat, by way of a small lever or push button located on top of the side plate with the handle. In the case of the lever drag reel the spool is released using the drag lever itself. When using multipliers for boat fishing the line is controlled throughout the release or cast by light thumb pressure on the revolving spool. Failure to do this can result in an over-run of the line, causing a tangle in the line. This is usually referred to by anglers as a bird’s nest or over run, and is the result of the line spool revolving faster than the amount of line actually leaving the reel.

In shore fishing and casting reels the risk of this can be minimised by the incorporation of braking system in the design of the reel. Common braking systems range from oil on the spool spindle and bearings through small centrifugal action brake pads made from nylon to hi-tech magnetic control of the rotating line spool.

The nylon brake blocks are fitted onto a cross bar on the spool spindle on the end of the spool, and as the spool rotates; these are pushed outward by centrifugal force, onto a braking drum. The resultant friction slows down the spool rotation. Different sizes of brake blocks are available to control the line spool speed; they only give the angler the minimum amount of control although more than that gained from oil alone.

A magnetic braking system can offer much more control to the speed of the spool. A magnetic field is set up between the spool and the magnets, causing it to slow down. This slowing down is dependent upon the number and power of the magnets in the reel and the distance of the magnets from the spool which can usually be adjusted by a control on the side of the reel. Reels without a braking system can have magnetic brakes fitted as an aftermarket add-on. These can be in the form of fully adjustable kits or simple fixed magnets glued inside the reel end plates.

The use of the above systems is mainly required when casting, for simple down-tide fishing heavy oil, such as car engine oil, on the spool spindle and bearings will give sufficient control of the line spool. A certain amount of braking pressure can be applied on some reels where the float of the spool is adjustable by turning a knob on the side plates. Care should be taken not to over tighten these as it can result in the spool spindle being warped.

Some braking devices work better than others and the best way to overcome the problems associated with line tangle is for the angler to learn to use the multiplier reel properly. When retrieving the line the angler should spread it evenly over the spool using the thumb if an automatic level wind is not fitted to the reel. A well laid line will help counteract over runs. A level wind is sometimes fitted to smaller reels and this mechanism moves back and forward across the face of the spool laying the line in a neat fashion. Unfortunately they will cut down casting distance and are frowned upon by experienced shore anglers.

An important feature of the multiplier reel is an adjustable slipping clutch mechanism. This is operated by a star wheel or lever drag control located beside the handle of the reel. It can be adjusted to fine limits so as to release line smoothly when under pressure from a fighting fish. Reels with star drags have a set of washers, metal, carbon fibre or plastic which in combination exert an adjustable pressure on the spool. The drag is tighten by turning the star wheel clockwise and slackened off by rotating in the reverse direction.

Lever drag reels use drag washers with a large surface area to provide the required friction against a drag plate. The lever drag is set up so that when the lever is against the limiter it is at the required pressure by turning a pre-set knob or wheel. Additional drag pressure can be applied by depressing the limiter button and shifting the lever forward. The drag is reduced by moving the lever backwards towards the free spool position.

The drag should be adjusted to give line when the fish exerts a pressure on the line of one

between one quarter and one third of its breaking strain ie 5 to 7kg for 20kg line this gives a margin of error when fighting the fish. The drag can be pre-set using a spring balance.

The frame and side plates of the reel should be of quality, corrosion proof materials. A feature on some multiplier reels is the quick ‘take-apart’ design offering large grip screws that allow the line spool to be easily removed and changed. It also permits easy access to the gears and other moving parts for maintenance.

The line spool must be filled to the correct capacity with line. This should be between 2 and 4mm from the rim of the spool for general boat and shore fishing but when learning to cast a part filled spool will rotate slower and will be less likely to cause an over run. Spools must also be strong enough to withstand the crushing effect of tightly wound line. The spool should be strong and lightweight, preferably of one piece machine cut aluminium alloy but glass fibre, carbon fibre, plastic can be used for shore fishing and cast metal can also be used from the boat. Heavy metal spools are unsuitable for casting due to their weight.

Ball race bearings or bronze bush bearings support the spindle, which runs through the centre of the line spool, giving a low friction revolution of the spindle and ultimately, the spool; hence the requirement for a braking system.

The majority of multiplier reels have a ratchet button fitted to the side of the side opposite the handle. This serves as an audible warning device when trolling or ledgering and helps ensure tangle free operation when setting up the reel on the rod and threading the line through the rod rings.

When and angler selects a multiplier reel care must be taken to ensure that the reel balances with the rod class and line to be used. In the case of shore fishing it is essential that the reel is designed for casting. This will greatly improve the working ability of all the equipment and give better sport.

A multiplier reel is basically a winch, and when used in conjunction with a rod, lifts fish and terminal tackle from the sea bed to the boat. It can be a complicated piece of engineering and must be cleaned in warm, fresh water after use. If necessary it can be scrubbed with an old toothbrush before being left to dry thoroughly. Oil and grease the reel according to the manufacturer’s instructions. Sparing use of a water repellent spray ie WD40 will aid moisture removal. Saltwater will, in time, corrode any reel destroying chromium plating, alloy parts, pitting bearing surfaces etc. A good multiplier reel, which is well looked after, and regularly serviced, will last for many years of angling and not let you down.

The multiplier reel is also known as a conventional or bait-casting reel in areas outwith the UK.

Larger versions of the illustrations in this feature can be viewed by clicking on the gallery below.

Advantages

- Gives smooth casts

- Light in weight

- Allows full use of spool capacity

- Gives efficient control of hooked fish

- Comfortable to use

Disadvantages

- Difficult to master when casting

- Comparatively expensive

- Requires regular maintenance and tuning

- Difficult to control in bad weather